A global leader in air-cooled chiller technology, York Chiller Solutions from Johnson Controls is at the forefront of providing efficient and sustainable cooling solutions. By offering the widest variety of energy-efficient water and air-cooled industrial and commercial chillers that are tailored to fit any comfort or process cooling application, YORK® stands by its commitment to reduce the earth’s carbon footprint and create healthier indoor environments.

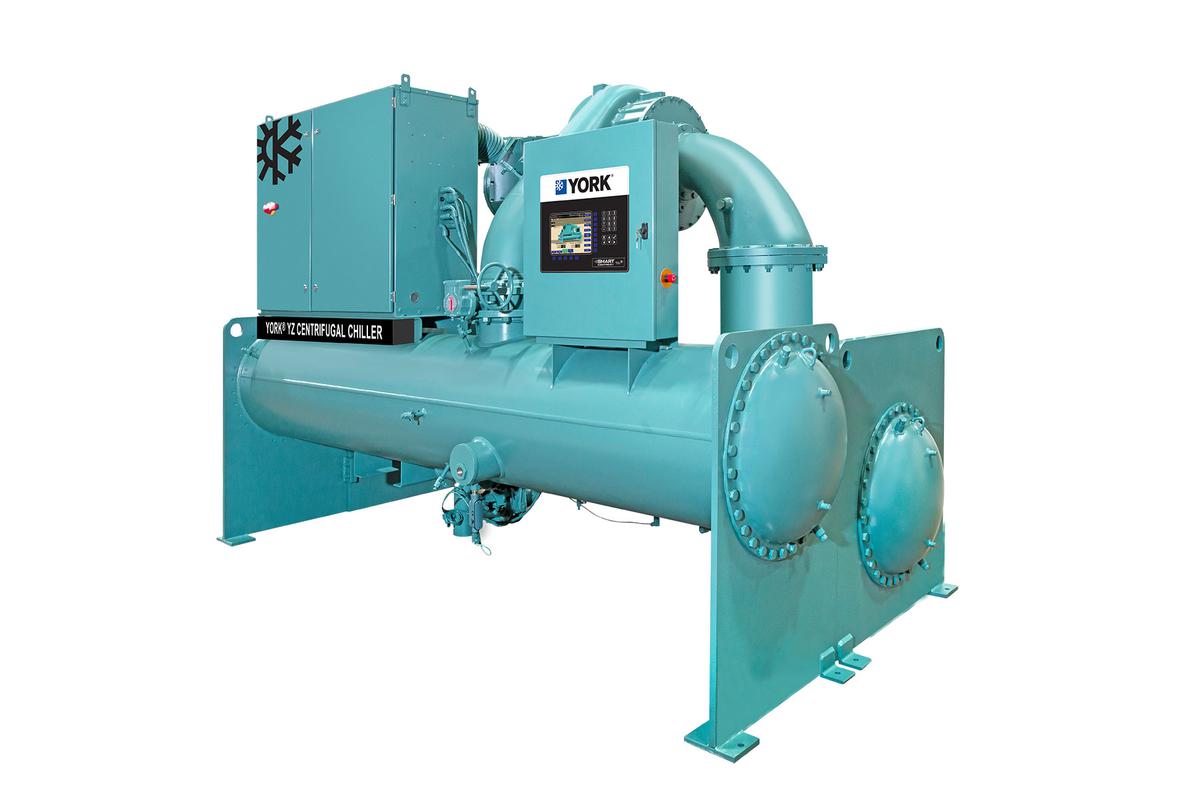

In line with its mission, Johnson Controls introduces another breakthrough innovation with the York YZ Magnetic Bearing Centrifugal Chiller, the first chiller fully optimized for ultimate performance with a next generation low-global warming potential (GWP) refrigerant—R-1233zd(E). For its marked efficiency, safety, availability, low environmental impact and cost, the YORK YZ Magnetic Bearing Centrifugal Chiller was recently awarded with the 2019 AHR Expo Innovation Award which honors the most exceptional products, systems, and technologies that push the boundaries of creativity, design, application, value, and market impact.

Sustainability that you can experience

To officially unveil the all-new York YZ Magnetic Bearing Centrifugal Chiller, a full-day business partners and media launch and program was held at the Century Hotel, Manila. Presented in partnership with Johnsons Control Inc. and YORK official distributor Stellar Equipment and Machinery Inc., a subsidiary of the Primer Group of Companies, the event gathered a handful of representatives from the media as well as VIPs and company executives.

As the brand puts a prime on the value of experience, select event attendees were taken on a tour to the facility area of Century Hotel where YORK chillers are installed. Led by Stellars’ Senior Sales and Marketing Manager Erwin Abad, the attendees got to find out for themselves how the all-new Magnetic Chillers differed from the hotel’s old chiller. During the tour, a YORK representative provided an insightful discussion about the technology and benefits of the YZ chiller. Later in the day, an exclusive talk was also held with Larry Kouma, the Team Lead of Applied Engineering at York Chillers, at the Kachina Room of Century Hotel to expand more about the technology behind York’s newest innovation. Mr. Kouma was also joined by Eu Boon Hoe, General Manager for the Distribution business under Asia Product and Distribution and Goh Chwee Guan, Regional Manager of Chiller Channel Sales.

Elevating lives while preserving the environment

As revealed during the brand talk, Johnson Controls applied a holistic approach to system design and engineering, optimizing every component around a carefully selected next generation refrigerant to ensure maximum sustainability and performance. For York, true sustainability means the lowest total emissions and adapting a chiller design to a new refrigerant is not enough. To attain the highest possible efficiency, York combines a low-GWP refrigerant with design optimizations that are specifically meant to maximize efficiency and minimize operation costs.

Recognizing the growing need for cooling systems that take into consideration its impact on the environment, the YZ Chiller uses an integral, variable speed drive and advanced magnetic bearing technology that features a single moving assembly suspended in a magnetic field that does not require lubrication.

This technology requires 80 percent fewer moving parts than traditional oil- or refrigerant-lubricated drivelines. The result is enhanced reliability, reduced maintenance and improved efficiency. Compared to traditional fixed-speed oil-bearing chillers, the YZ chiller delivers up to 35 percent annual energy savings.

Finally, the YZ uses an optimized single stage design to provide industry-leading real- world energy efficiency. This technology enables the chiller to operate with condenser temperatures below the evaporator temperatures, eliminating the need for a water-side economizer, which simplifies the system, requires less mechanical room space and saves money on components, piping, controls and maintenance.