We’ve hit a technological plateau with firearms today. We continue to see a few small innovations here and there, but since the development and widespread use of the metallic cartridge, it’s quite safe to say that we’ve hit a wall. There have been some promising technologies, such as caseless ammo, that fell flat, but for the most part, we might just be where we’re going to be for a while yet. To appreciate exactly where that is, though, we should take a look at where we’ve been.

At the very start of firearms development (at least in a form like those we know now), what we had were big, heavy, unwieldy, and just a little less dangerous for the operator than it was for the target. They didn’t do a lot to help users aim, they were huge, and all kinds of unpleasant, but the flash, sound, and smoke produced by even just a handful of these would have been enough to scare away any combatants who might be advancing with poleaxes or pikes.

These firearms were little more than bulky, metal tubes with a touch hole into which some form of ignition could be introduced to set off a load of black powder behind a projectile. It was a cutting-edge weapon in the 13th century, and in the places it was used—first in China, and then through to the Middle East, Europe, and Southeast Asia—it proved to be terrifyingly effective. While a bow could offer faster, more accurate fire, this firearm precursor was much easier to train in and use.

For the longest time, these weapons were operated by holding the loaded weapon in one hand, and then touching a slowly burning segment of cord to a measure of powder in a recess in the back of the weapon. The recess, otherwise known as a “pan,” had a hole at the bottom which led into the back of the barrel, wherein a propellant charge rested behind the projectile. The ember would ignite the powder in the pan, sending sparks down the hole, igniting the main charge, and sending the projectile flying. The logical thing to do would have then been to tie the rope to the weapon so you wouldn’t easily lose it in combat. After that, it was a quick step to affix the whole weapon onto a stock, and the smoldering rope to a moving arm that could be actuated with a lever, moving it to the pan. Such was the evolution to the matchlock. The lever was eventually replaced with a more precise trigger, giving us the rough shape of the firearm we know today.

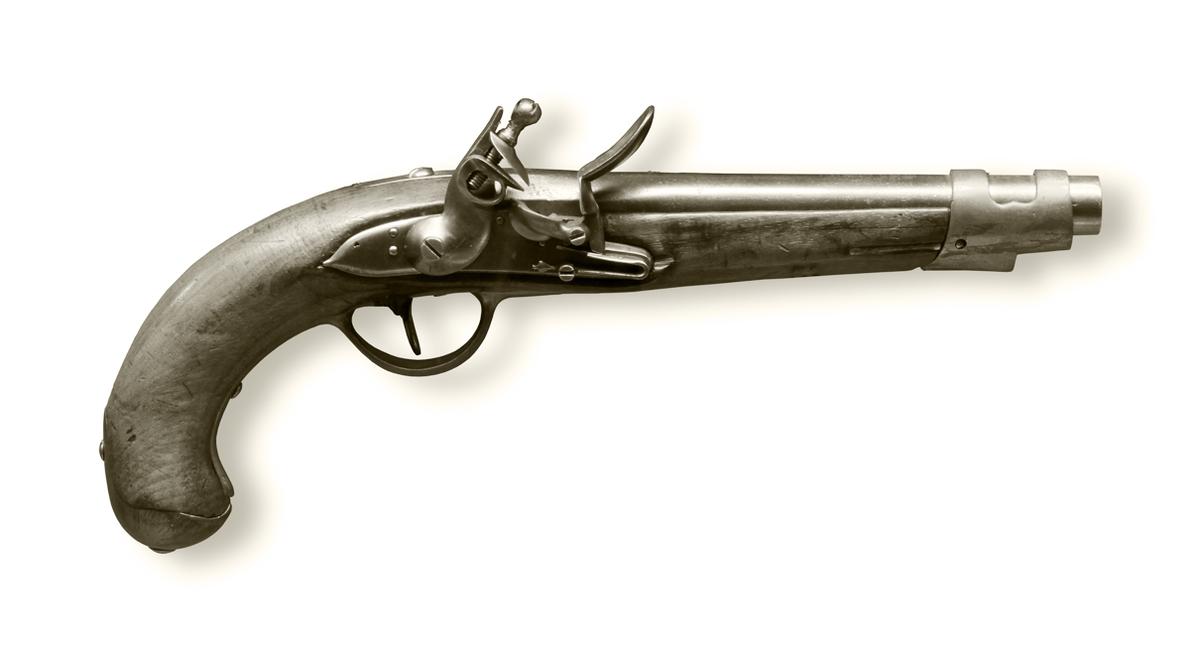

The problem with the matchlock is that the match could very easily go out. Whether it was from the rigors of combat or the act of shooting, an ember isn’t the easiest thing to keep alive. This led to the development of a more reliable system two centuries later. The flintlock, which replaced the smoldering rope with a piece of flint and a striking surface, was a great improvement over the previous matchlock. It also gave up the flashpan for the smaller priming pan which worked in essentially the same way, though with the need to use less powder. This also allowed the production of smaller, handier pistols that could be charged and kept handy in a way matchlocks just couldn’t.

After the flintlock, there was a short-lived sidestep in the ignition process. The wheellock operated in a very similar fashion to the flintlock, but instead of a single strike that sends sparks into the priming pan, the wheellock worked much like a modern-day cigarette lighter. The heart of a wheellock is a spring-loaded wheel to which a hardened, grooved metal shaft is attached. A movable arm holds a piece of pyrite which can be moved to contact the grooved shaft. The wheel is wound, the pyrite is put in contact with the shaft, and once the trigger is pulled, the wheel and shaft spin, scraping the pyrite much like your cigarette lighter would do it, and creating a shower of sparks that ignites the priming charge, which sends fire down to the main charge, and launches the projectile out the bore of the weapon. This was a more reliable form of ignition than the flintlock as there were far more sparks and a greater chance of the powder catching, but what caused its demise was the complexity of the mechanism. Springs, sears, latches, and lots of metal meant a lot of precise work, and at a time when everything was made by hand, only the wealthy could afford such engineering. It’s also a reason not many survive today. The complexity of the design, and the fact that after firing, they could (and would) be used as bludgeons, meant that not many working examples survive to this day.

This takes care of the first part of firearms development. Next month, we’ll be taking a look at the technology we built on from there.

Also published in GADGETS MAGAZINE July 2016 Issue.

Words by Ren Alcantara