Where does shredded paper go? Ideally, shredded files should go in the recycling bin. However, a number of offices direct them straight to the trash. Which is a waste of valuable resource.

In response to this, Seiko Epson Corporation (SEC) has developed the world’s first compact office papermaking system capable of producing new paper from securely shredded waste paper without the use of water.

Dubbed “PaperLab,” Epson plans to put this project into commercial production in Japan come 2016; sales in other regions to be decided at a later date. Businesses and government offices that install a PaperLab in a backyard area will be able to produce a variety of paper goods: from office paper, business card paper, to paper that is colored and scented.

A developmental prototype of the PaperLab was demonstrated at the Epson booth at the Eco-Products 2015, an environmental exhibition that took place at the Tokyo Big Sight (Tokyo International Exhibition Center) last December 10 to 12.

As one of the trailblazers in the world of printing, Epson has been deeply involved with paper used for its printer products. With this in mind, the company set out to develop technology that would change the paper cycle. With PaperLab, Epson aims to give new value to paper and stimulate recycling.

PaperLab features:

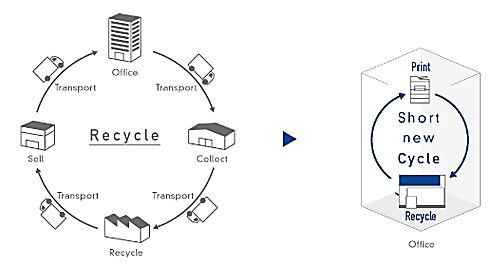

1. Office-based recycling process

Ordinarily, paper is recycled in an extensive process that typically involves transporting waste paper from the office to a papermaking (recycling) facility. With PaperLab, Epson is looking to shorten and localize a new recycling process in the office.

2. Secure destruction of confidential documents

Until now enterprise has had to hire contractors to handle the disposal of confidential documents or has shredded them themselves. With a PaperLab, however, enterprise will be able to safely dispose of documents onsite instead of handing them over to a contractor. PaperLab breaks documents down into paper fibers, so the information on them is completely destroyed.

3. High-speed production of various types of paper

PaperLab produces the first new sheet of paper in about three minutes of having loaded it with waste paper and pressing the Start button. The system can produce about 14 A4 sheets per minute and 6,720 sheets in an eight-hour day.

4. Environmental performance

PaperLab makes paper without the use of water. Ordinarily it takes about a cup of water to make a single A4 sheet of paper. Given that water is a precious global resource, Epson felt a dry process was needed.

In addition, recycling paper onsite in the office shrinks and simplifies the recycling loop. Users can expect to purchase less new paper and reduce their transport CO₂ emissions.

PaperLab technology

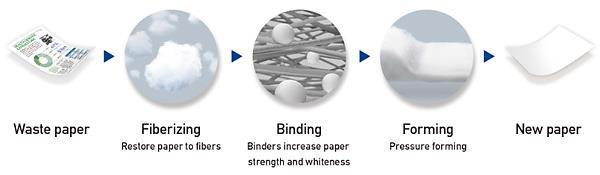

Epson has also developed Dry Fiber Technology without water, a new group of technologies for the PaperLab. Dry Fiber Technology consists of three separate technologies: fiberizing, binding, and forming.

Epson aims to help customers increase operational efficiency by providing high-speed, low-power business inkjet printers that deliver images of amazing quality at a low cost per print. And by employing PaperLab to convert used paper into new, the company believes that offices of all types will fundamentally change the way they think about paper.